- Home

- Custom Sheet Metal

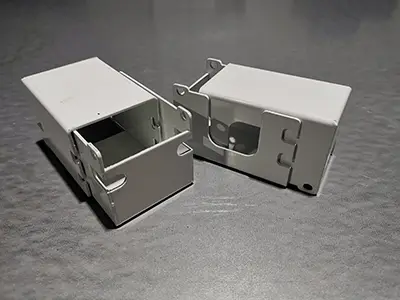

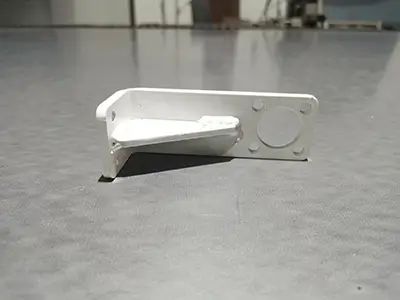

Custom Sheet Metal

Youyun Automation can customize sheet metal parts according to your requirements.

We provide laser cutting, bending, welding, painting and other one-stop services.

We not only mass produce parts for customers, but also make small batch samples. No MOQ is set.

The lead time is about 1-15 days.

In addition, the dedicated engineers will provide you with professional design advice and quick response quotations. Our response time is 24 hours.

Our main processing material is hot plate cold and plate stainless steel.

Our sheet metal products are mainly used in automation equipment.

The following are the success stories of our company. Welcome to contact us!

What technology we use

At Youyun Automation, we leverage cutting-edge technologies and advanced manufacturing processes to deliver superior products that meet the highest industry standards.

Cutting

Take utilizing laser cutting technology for sheet metal fabrication, and get exceptional precision, versatility, speed, and cost-effectiveness. It enables the manufacturing of high-quality components with intricate designs, meeting the diverse needs of industries such as automotive, aerospace, electronics, and more.

Welding

As a leading automation component manufacturer, we understand the critical role that welding plays in ensuring the structural integrity and durability of our products. Our skilled welders, each one has more than 20 years of experience in welding, utilize advanced welding techniques to join metal components with precision and strength. Whether it’s machine frames and bases or customized components, our welding technology ensures reliable and robust connections, capable of withstanding demanding operational conditions.

Bending

Bending sheets of metal through CNC press braking imparts improved strength and structural integrity to the fabricated components. By utilizing the appropriate bending techniques, the metal can be shaped in a way that reinforces its strength, ensuring the final product is robust and durable. Which enables the fabrication of complex geometries and various forms. This allows for the creation of a wide range of products, including enclosures, brackets, frames, channels, and more.

Spray-painting

By utilizing our paint spraying services, thorough cleaning, sanding, and priming guarantee a smooth and even surface, and protection of your sheet metal components. Our expert technicians, attention to detail, and commitment to quality ensure that the painted finishes meet your expectations and requirements.